Keyword: electrostatic spray gun, liquid electrostatic spray gun ,automatic electrostatic spray gun, manual electrostatic spray gun, paint spray gun, water spray gun, liquid coating system, electrostatic spray coating machine,

Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Hotline:86-13926859125

Design and planning of coating process and production line for new energy resources automobile.

Abstract: with the improvement of people’s living standards, the demand for cars is also increasing year by year. With the rapid development of new energy vehicles, a variety of new energy vehicle bases have emerged all over the country. Energy saving and new energy vehicles are one of the ten major fields of made in China 2025, the focus of international automobile technology competition in the future, and the only way and rare strategic opportunity for the transformation and upgrading of China’s automobile industry and the realization of the dream of a strong country. At the same time, under the background of energy restriction and environmental pollution, our government regards the development of new energy vehicles as n important measure to solve energy and environmental problems, bull a resource-saving, environment-friendly society and achieve sustainable development. Among them, lightweight, multi-material body represents the main development direction of new energy vehicles. The lightweight body design, which reduces the weight of automobile body and adopts weight loss measures such as structural improvement and new material application, is changing the body structure and integrating a variety of materials, which will inevitably bring about changes in painting technology and mode of production. In this paper, the painting technology and production line design and planning of new energy vehicles are discussed.

Classification of new energy resources vehicles

The new energy resources vehicle includes: Pure electric vehicle, the augmented electric vehicle (EV), the hybrid vehicle, fuel battery electric vehicle and the hydrogen engine vehicle, other new energy vehicles (such as the super capacitor, the flywheel and so on high efficiency energy storage device, the air power, the methanol vehicle, solar energy vehicle) and so forth. In China, the new energy resources vehicle mainly refers to the pure electric vehicle, the augmented electric vehicle (EV), the plug-in hybrid vehicle and the fuel battery electric vehicle.

2 The Role of Auto Body Painting Process

Automotive coatings refer to the film formed when organic matter in a stream or powder is applied to another object. Usually, we refer to this film as a coating, and then apply it to a clean car body, and then perform the related process, such as the formation of the drying steps.

The film is the entire process of car painting. There are many reasons for painting the surface of a car, the most important being that it plays a decorative role in the vehicle. By painting the body, we can show the different colors of the car, and make the body more three-dimensional and excellent, so as to meet the beauty and pleasure of people's current personal needs to a great extent. Secondly, the paint on the car can form a protective layer to protect the surface of the car, but at the same time this is the most important goal of the car paint.

Coating technology of new energy resources automobile

3.1 Combined painting processes to reduce environmental pollution

The original production process of the body paint shop used solvent based paint. The exhaust gas of spraying, painting and drying was treated by Venturi.

The pre-treatment is completed by the phosphating process workshop, and the body is delivered by the driver driving the transport car according to the needs. The process contains exhaust gases

The disadvantages of incomplete treatment, low material utilization, difficult wastewater treatment and low transportation efficiency. Through the consolidation of the painting process, the front

Water washing transportation rail system is added, silane zirconium pretreatment, spraying process is switched from solvent-based spraying process to water-based spraying process.

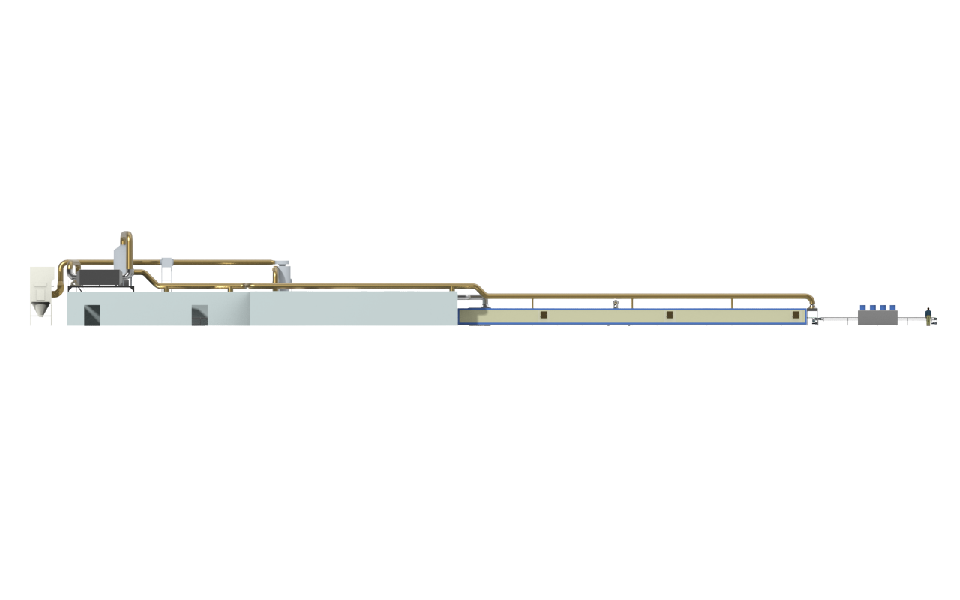

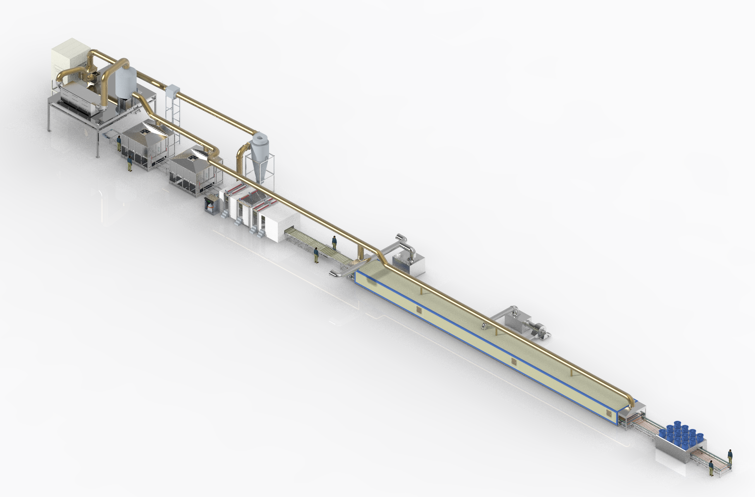

The spraying method is changed from manual spraying of outer plate to automatic spraying, and the waste gas is treated with zeolite wheel concentration system + RTO incineration technology, and a preheating chamber, primer chamber and leveling chamber are added. This process aims to merge and integrate raw material substitution, production process control, end treatment and other links. The independently designed subsystems or modules are combined to form a complex large system, which minimizes the generation and emission of volatile organic compounds (VOCs), improves the body painting capacity, and ensures that the exhaust gas and wastewater emissions meet industry standards.

(1) separate body painting technology of aluminum alloy skeleton + non-metallic panels. The split body of aluminum alloy skeleton + non-metallic panel (cabin or skeleton is aluminum alloy profile, body cover is plastic part, carbon fiber (CFRP), fiber reinforced composite material (FRP), sheet mould plastic (SMC), etc.). This kind of body is generally coated separately and sent to the assembly workshop for assembly. The main contents are as follows: (1) coating process of aluminum skeleton (or frame). Aluminum skeleton (or frame) painting process: for new energy vehicles

The aluminum skeleton is a non-exposed part, the aluminum alloy frame is located at the bottom of the car, only need to consider anticorrosion, oil resistance or heat resistance, no need to consider the appearance quality, so the process is relatively simple, only electrophoresis primer can be considered. Among them, the pretreatment adopts the special film (passivation) process of aluminum parts, and the electrophoresis adopts the cathodic electrophoresis process of the bottom surface of medium and thick film. (2) coating process of non-metallic panels. The painting process of non-metallic panels: the outer panels (door, wing plate, engine cover, suitcase cover, top cover) are non-metallic, so the painting workshop saves complex pretreatment and other procedures. At present, the key technology of carbon fiber parts in China has not been fully mastered, and the appearance quality can not be guaranteed, so for carbon fiber panels, solvent 3C2B process is recommended at present. With the development of technology, the improvement of materials and the maturity of carbon fiber fabrication process, the trend of process development in the future is compact 3C1B (B1B2) process. In addition, in the pre-treatment of the use of chemical cleaning and dry ice cleaning, dry ice cleaning or chemical cleaning is preferred. (2) the split body of aluminum frame + CFRP cabin + non-metallic panel. Painting process CFRP cabin + non-metallic panel split body (only the small frame is aluminum alloy parts). This kind of body generally also uses the split painting, the painting is sent to the assembly workshop for assembly.

The body is composed of "aluminum frame + CERP vehicle and ship + non-metallic parts". Three kinds of parts are painted separately, in which the carbon fiber vehicle and ship are generally collected.

With primary color, do not paint: aluminum frame, only need to carry on the electrophoresis painting: the non-metallic recommended cover parts are painted separately, similar to the bumper coating line.