Keyword: electrostatic spray gun, liquid electrostatic spray gun ,automatic electrostatic spray gun, manual electrostatic spray gun, paint spray gun, water spray gun, liquid coating system, electrostatic spray coating machine,

Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Hotline:86-13926859125

Product introduction

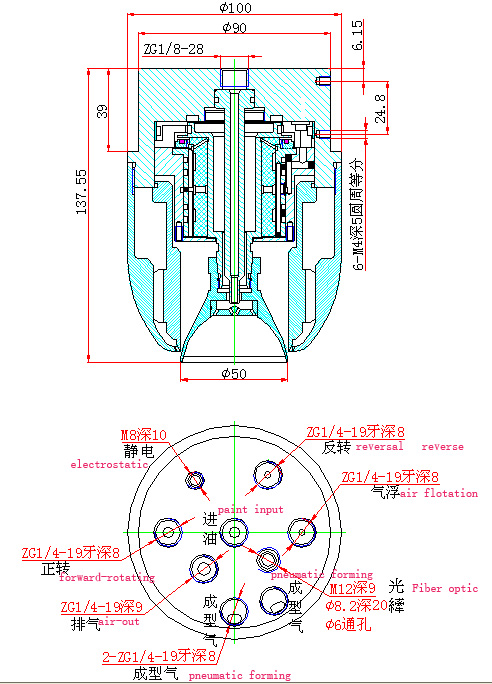

PMQ series high speed static cup is a skillfully designed, flexible and efficient industrial coating rotary atomizer. It is a self-designed, high-tech product with international competitiveness.

Characteristic

Strong atomization

ability: the world's leading turbine motor has a high speed, which ensures that

the solvent and waterborne coatings are fully atomized.

High transfer

efficiency: easy to control forming design, can confirm the paint rate up to

80%, aluminum alloy and titanium alloy cup head material, combined with

different needs of the design of the forming cover, can meet the requirements

under different conditions.

Applicable

coatings: solvent and water-based coatings.

Applications:

automotive parts, aluminum profiles, wood industry, motorcycles, bicycles,

hardware, electronics, containers, agricultural and construction machinery.

Instructions for the use of air motors

1. The requirements of the gas source are as follows:

1, filter particles less than 0.01 microns;

2. The oil content is less than 0.01mg/m3,20 C;

3. The dew point of the operation pressure is less than 3 TD;

4, the pressure of the stable spindle bearing is 5.5~7Kgf/cm2;

5, the service life of the filter core is 250 days (6000 hours) or the pressure drop 0.1MPa must be replaced in time (not allowed to clean).

Two. The starting order of the pneumatic motor is as follows:

1, check whether the air floatation pressure of the air motor is stable at 5.5~7Kgf/cm2;

2, first of all, turn on the air floatation gas and use the hand to move the spray cup to check whether the rotor can rotate freely.

3. Turn on the rotary gas and adjust the pressure according to the required speed.

4. Open the forming gas and adjust the pressure according to the need of forming.

5, open the oil switch;

6, open the electrostatic switch.

Three. Turn off the pneumatic motor in order to turn the start-up sequence in operation (6, 5, 4, 3, 2): Attention: 1, to ensure that the vent is smooth, otherwise it will affect the speed of the motor.

2, to ensure that the pneumatic motor is stopped, the air source can be turned off.