Keyword: electrostatic spray gun, liquid electrostatic spray gun ,automatic electrostatic spray gun, manual electrostatic spray gun, paint spray gun, water spray gun, liquid coating system, electrostatic spray coating machine,

Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Hotline:86-13926859125

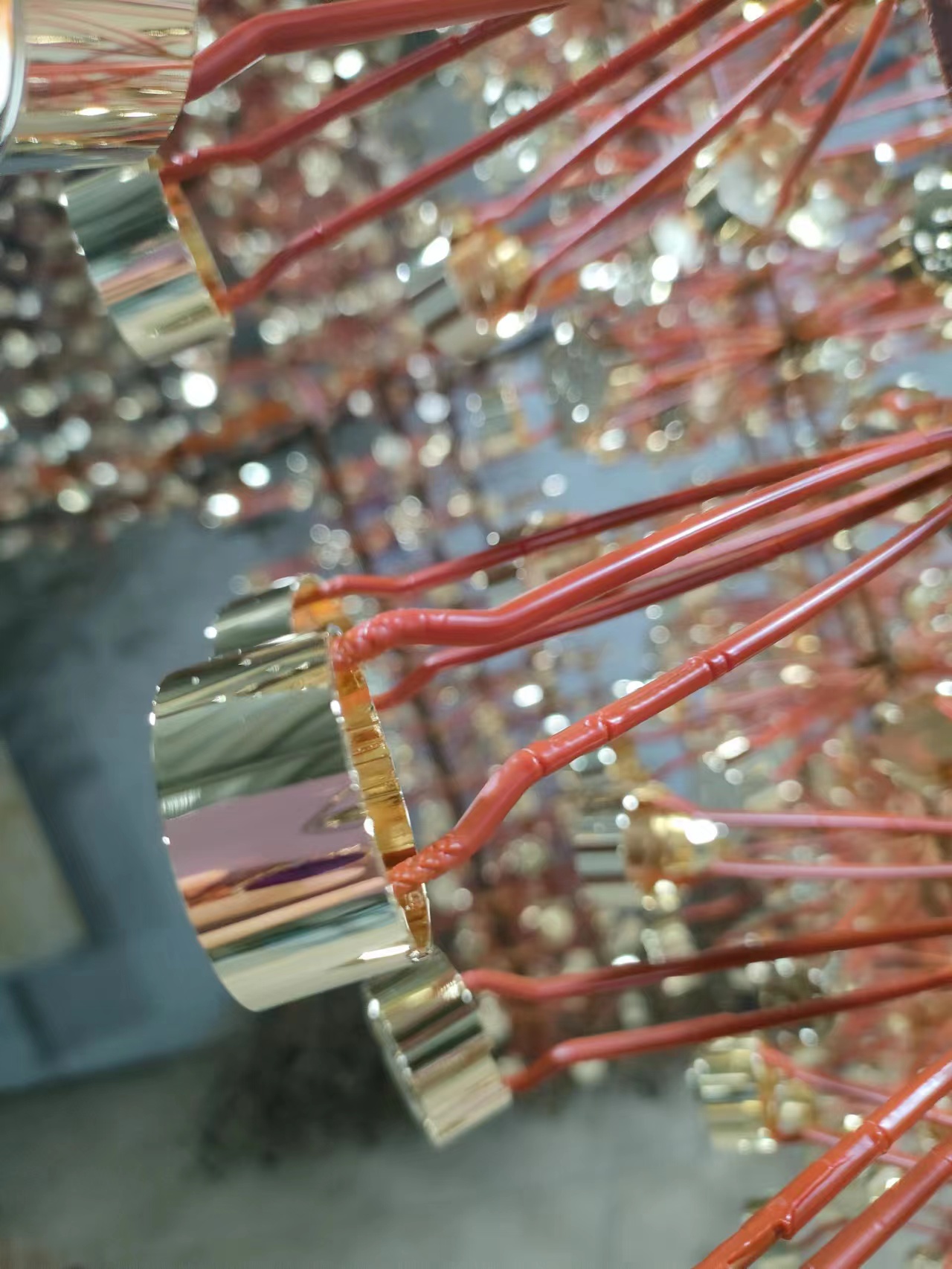

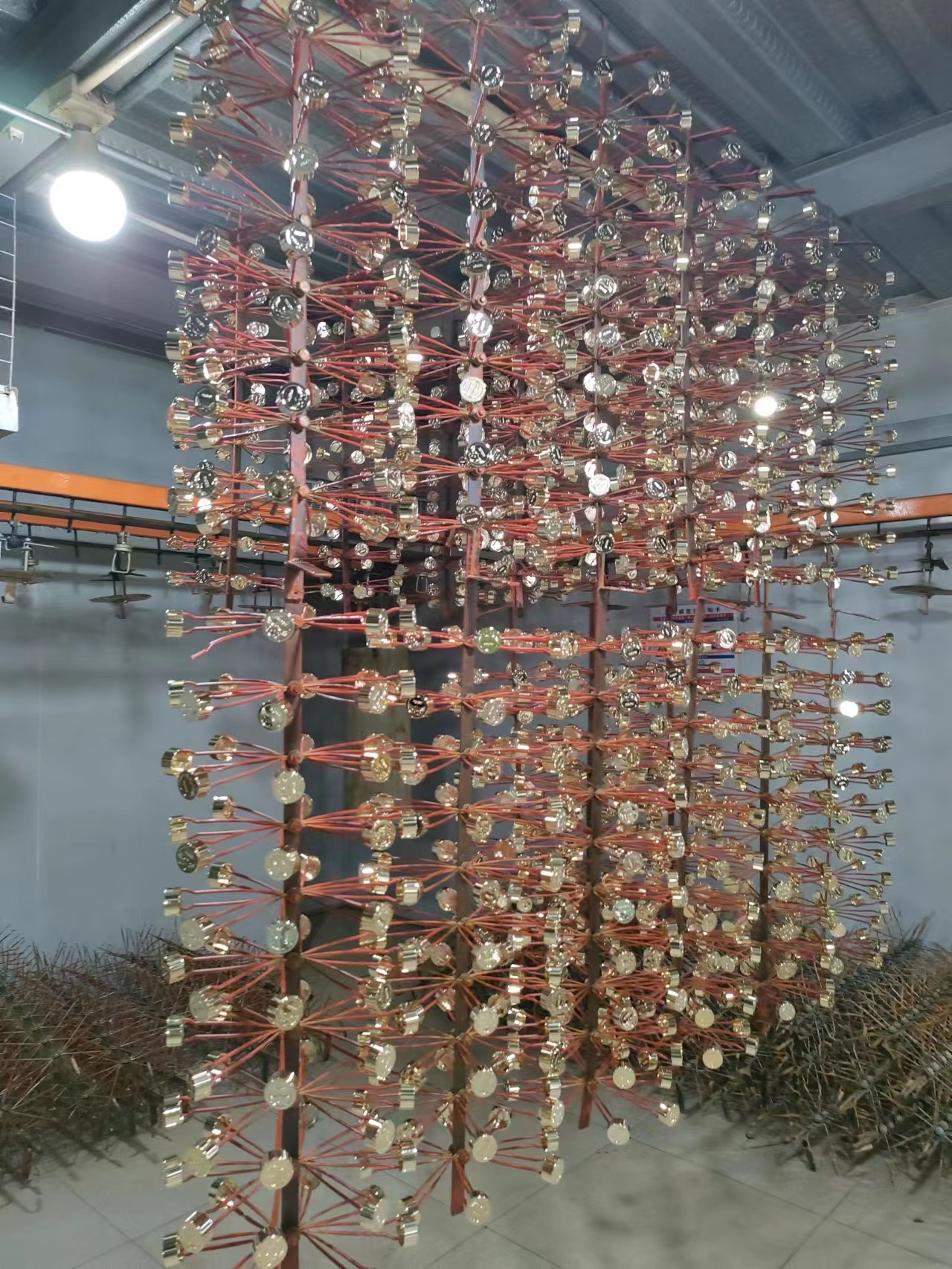

The HDA automatic rotating bell spray machine for furniture, hardware parts, glass packing bottle, machinery and automotive parts for high efficiency liquid paint coating.

what's the different between liquid and powder coating?

Which of the liquid property is important in coating technology?

Surface tension is the key parameter which determines good leveling and wetting of a coating. Surface tension is involved in almost every way in coatings technology i.e., dispersing, wetting, leveling, adhesion, etc

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobiles, and bicycle frames. Advancements in powder coating technology like UV curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF (medium-density fibreboard) to be powder coated due to the minimum heat and oven dwell time required to process these components

Speed and efficiency

If you’re painting a large surface area such as a commercial floor, ceiling or roller door, industrial spray painting can cover a large area, very quickly. This can reduce the time it takes to do a job, minimising downtime for your business, as well as reducing the cost of the job.

Controlled atomisation

electrostatic spray painting is one of the most popular industrial spray painting systems on the market today. An electrostatic sprayer pumps the paint under very high pressure via a specialised hose into a small hole in the nozzle of the sprayer. Applying thicker, or more thixotropic paint material requires a larger spray tip nozzle. It also requires higher pressure to ensure the paint particles are atomised to produce a fine mist.

Electrostatic spray

Another popular industrial spray painting system is HVLP (high-volume, low-pressure). HVLP spray systems use a lightweight air turbine instead of a large air compressor to supply the air to atomise the paint. The air is supplied at a much lower pressure and speed. This means the amount of overspray and material wastage is vastly reduced compared to conventional air spray – resulting in a much cleaner spray environment. HVLP is the ideal method of spray application when applying a metallic paint finish.

Industrial spray painting systems give a smooth and even finish, which can withstand wear and tear as well as harmful corrosion. Paint particles in the form of tiny droplets are expelled at pressure to produce a mirror like or factory like finish on a variety of surfaces. These include commercial roofs, shopfronts, cladding and other surfaces that require a tough, quick-drying paint.

Preparation before spray painting

Regardless of the industrial spray painting system that’s used, the surface must be properly prepared prior to spraying. Preparing the surface can involve grit blasting, cleaning & degreasing, sanding, removal of loose and delaminating material, and masking and sheeting any areas that are not to be painted. Any surface to be painted must always be properly prepared.